TAG Engineering offers a wide array of machining capabilities including C.N.C. machining, Proto-type machining, and deburring.

TAG Engineering offers a wide array of machining capabilities including C.N.C. machining, Proto-type machining, and deburring.

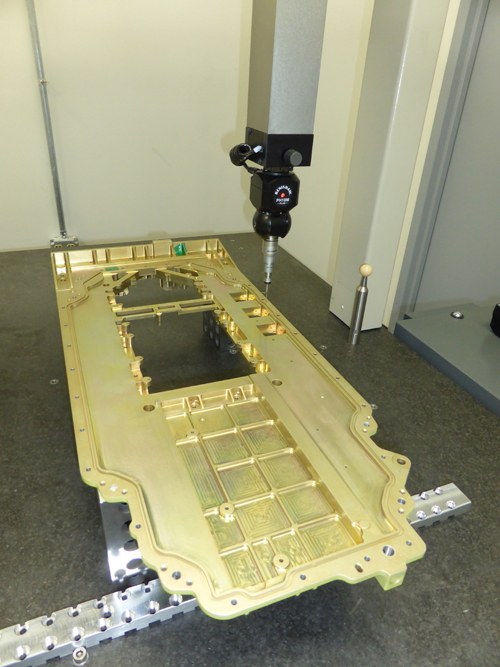

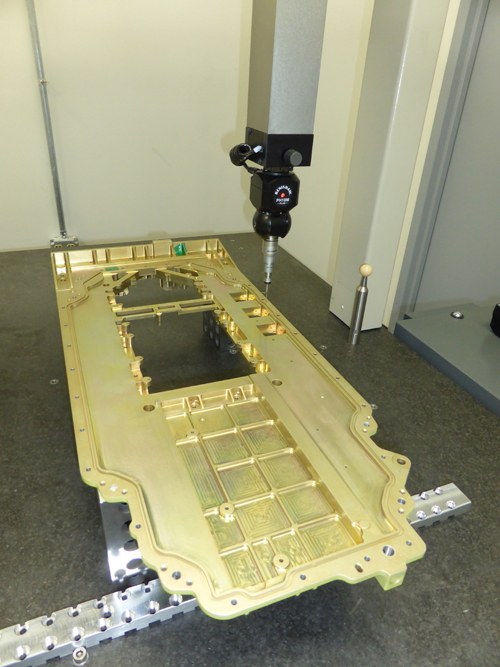

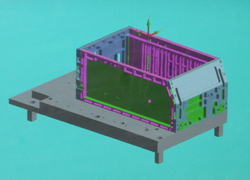

All vertical milling machines have true 4th axis capabilities to machine parts up to 60"x30"x30".

With extensive machining capabilities, TAG delivers a variety of superior quality products and entire assemblies.

Quality Policy Statement:

Quality Policy Statement:

It is the goal of TAG Engineering Inc., through continuous improvement, to manufacture product that conforms to or exceeds customer requirements for quality.

The primary goal of our Quality Assurance personnel is to maintain excellence in both quality and delivery. This standard of excellence is achieved by a "Quality Team". With the aid of Coordinate Measurement Machines and a CAD software stations, we strive to ensure every product will conform to, or exceed, the data provided regardless of the format.

At TAG, we haveimplemented a AS9100 certified Quality System. A computerized Statistical Process Control system is also utilized when required by a customer or deemed necessary by a member of our Quality Team.

With this attention and commitment to Total Quality, TAG Engineering has been awarded the status of "Certified Supplier” and "Preferred Supplier" by major aerospace companies. This enables us to ship product directly to the point of usage.

Read more: Quality Control

TAG Engineering offers a wide array of machining capabilities including C.N.C. machining, Proto-type machining, and deburring.

TAG Engineering offers a wide array of machining capabilities including C.N.C. machining, Proto-type machining, and deburring.

TAG is committed to staying up-to-date with the technology of today’s aerospace industry by offering aluminum vacuum brazing services. Certified to vacuum braze by leading aerospace and defense companies, TAG assemblies can be pressure, flow, and burst tested here in our facility to meet customer specifications.

TAG is committed to staying up-to-date with the technology of today’s aerospace industry by offering aluminum vacuum brazing services. Certified to vacuum braze by leading aerospace and defense companies, TAG assemblies can be pressure, flow, and burst tested here in our facility to meet customer specifications.

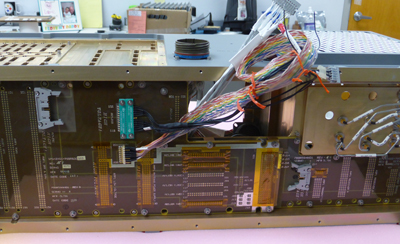

At Tag you will find value added services such as next higher assembly of the housings and enclosures to include installation of electronic components, wire harnesses and hard lines.

At Tag you will find value added services such as next higher assembly of the housings and enclosures to include installation of electronic components, wire harnesses and hard lines.

Quality Policy Statement:

Quality Policy Statement: Our Computer's are equipped with Unigraphics CAD/CAM software allowing us to take your CAD designed model and create the code for the CNC machines for accurate realization of your design.

Our Computer's are equipped with Unigraphics CAD/CAM software allowing us to take your CAD designed model and create the code for the CNC machines for accurate realization of your design.